We design and develop foundry tooling and casting processes through accurate casting simulations and dedicated mold design for а wide variety of industries: automotive, defense, medicine, appliances, etc.

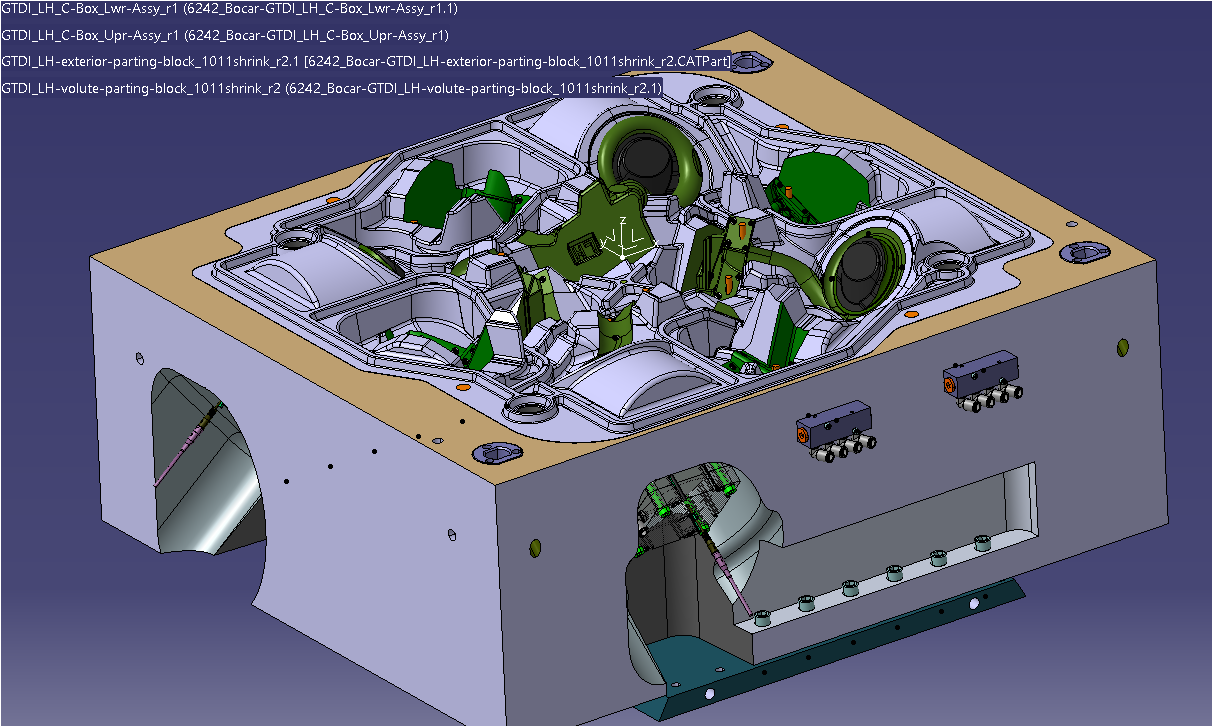

Advanced fully parametric Siemens NX / Catia mold design for CPC, LPC, HPDC, gravity, tilt pour, core boxes and injection molding.

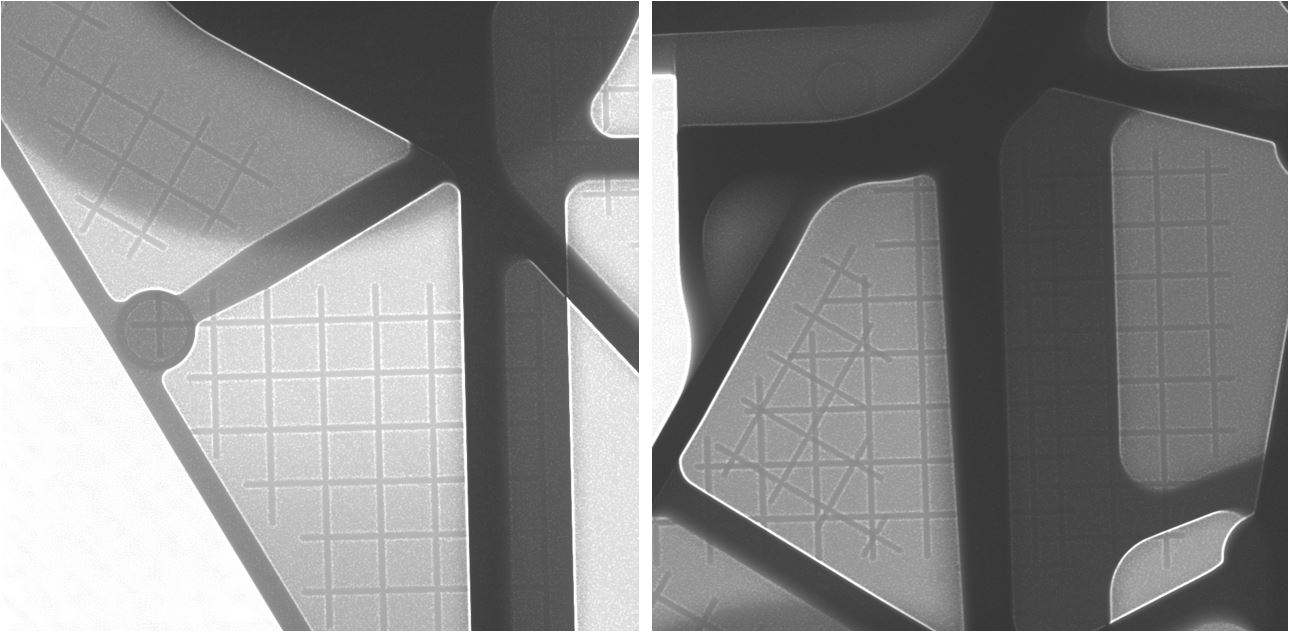

Accurate process simulations to optimize casting quality and mechanical properties before production.

Consulting through the whole process: from process selection and part design to the on-site casting technology setup.

VIMANA Engineering Ltd. is an engineering and services office representing Anderson Express Inc. in Bulgaria. Located in Pleven, a city with rich traditions in foundry equipment design and production along with the great history, we put our experience on your side and give an advantage to your tooling and casting business.

From accurate simulations to on-site support, we do apply individual approach to every project. If a full service is needed, including tooling production, we rely on the manufacturing excellence of our partners Anderson Global / WAFCO, USA.

Experienced team specialized in structural and suspension parts design, simulation and production, with deep knowledge in CPC, LPC, HPDC and gravity / tilt pour casting processes.

Advanced casting process simulations for optimized quality, guaranteed mechanical properties, reducing risks and costs.

Every project receives dedicated attention from concept to completion, ensuring solutions tailored to your specific requirements.

Access to Anderson Global / WAFCO state-of-the-art tooling production facilities ensures precision manufacturing to the highest standards.

Rigorous processes and proven methodologies guarantee excellent casting quality and mechanical properties in samples and production parts.

Serving automotive, powertrain, medical, defense and other industries, considering the specific requirements.

Lying on the long-term traditions in the foundry business, we continue decades of engineering experience and heritage.

From tooling design and simulations to technology setup and troubleshooting: full-cycle support for your casting needs.

Hands-on casting technology setup, problem troubleshooting, and consulting servicesremotely or on-site.

CPC and LPC tooling design for structural and suspension parts with optimized geometry.

Multi-cavity counter pressure casting (CPC) and low pressure casting (LPC) mold design. Specialized in structural and suspension parts for automotive with focus on mechanical properties and casting quality.

HPDC tooling design for high-volume production with precision and efficiency.

High pressure die casting (HPDC) tooling design for vide variety of castings: lighting, appliances, surveillance, military, power tools, etc.

Advanced engineering solutions ensuring optimal cycle times and dimensional accuracy.

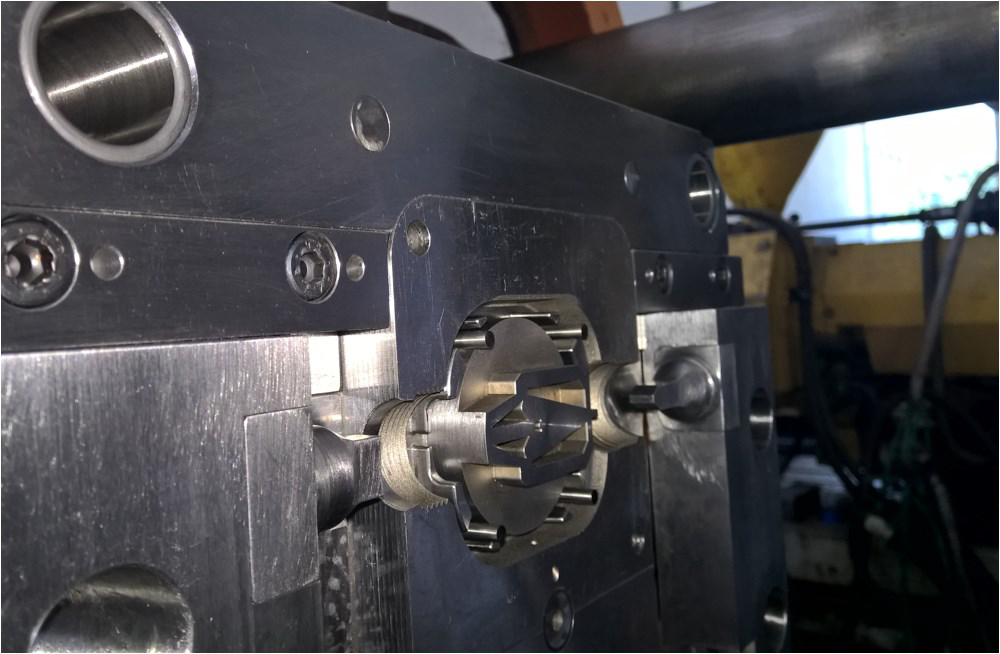

Organic and inorganic core box design for complex internal geometries.

From simple 2-part vertical split to complex organic and inorganic core box design, we can design your tool for sand cores needed. Shooting process simulations are available upon subcontracting and thus delivering full engineering services.

injection molding tooling design for random applications.

Variety of technical and aesthetic plastic parts for every need. Versatile solutions for various part sizes and production volumes, from prototype to high-volume manufacturing.

Advanced process simulations leading to free of defect castings.

Flow and thermal casting process simulations analyzing mold filling, solidification, and alloy behavior. Identify potential defects early, optimize gating systems, and reduce development time and costs while ensuring superior part quality.

Casting process setup, troubleshooting, and consulting at your facility.

Comprehensive on-site services including casting technology setup, problem troubleshooting, and expert consulting. Hands-on support directly at your production facility to resolve issues quickly and optimize your casting processes for maximum efficiency.

Partner with VIMANA Engineering for dedicated tooling design and individual approach.